Harvesting honey has never been easier

Paradise Honey is the world leading manufacturer for professional honey production equipment and EPS beehive products. They have developed a line of high quality honey production equipment, honey processing equipment and BeeBox beehive products.

All of their products have been tested in large 3000+ hive beekeeping operations, of which yealding average of 120-200 tons of honey/year. This ensures that the Paradise Honey products delivers what is expected. As a result we are offering tried and tested products that have proven to deliver efficiency, security and long term durability. Investing in this high quality production equipment and beehive products is a decision for a life time. When you want to get your honey production business into the next level, please contact us. hives for their needs.

EPS BEEBOX BEEHIVES

The BeeBox beehive system is the result of 40 years of beekeeping and development experience on the biggest beekeeping operation in Scandinavia. They have been tested as well in harsh environments facing ± 50°C in Northern Europe, arctic Russia, Australia, New Zealand etc.

The beehives are made of food grade, extra hardened, expanded polystyrene (EPS) with a density of over 100 kg/m³. In proper use, the hives will easily last several decades. In order to save space during transport, the boxes are supplied unassembled.

EXTRACTING LINES

Paradise Honey have developed a line of high quality honey production equipment customisable for the needs of our customers.

This wide range of honey extraction equipment is suitable for both large and small-scale honey producers. All our products have been tested in large 3500+ hive beekeeping operations.

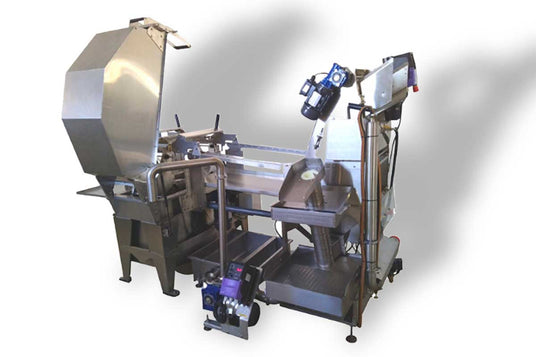

UNCAPPING EQUIPMENT

Forget slow uncapping process by hand – lift honey frames into the slide feed or chain feed magazine and the uncapping line does everything faster and more efficiently.

We provide powerful uncapping machines for maximum speed and efficiency. Forget slow and messy uncapping by hand and get to know our uncapping machines.

WAX PRESS SYSTEMS

Continuously operating press system for capping’s honey and wax treatment. The mix drops into the hopper cone and is pushed forward by the screw. The constantly increasing pressure forces the honey to flow through the holes in the strainer plates and drop into the honey sump below. The wet wax parts are stopped by the filter plates along the screw. The dry wax is carried forward to the end of the screw where it is collected in the basin. The strainer works also as a pre-filter. The best result comes when the mixture is gently pre-heated.

The honey and wax press system is excellent for cold mixtures process, coming straight from the beehive as well. All the models have inverter force and capacity control for the best performance for different types of honey which is time saving and energy. The result of this process offers a higher honey quality and super low HMF.

HONEY ROCKET SYSTEMS

New continuously operating Honey Rocket System with Turbo is designed for commercial honey and wax separation especially to be used together with a stirer tank system and also when the space for honey extraction equipment is limited, for instance inside a mobile honey extraction trailer. The new Turbo Honey Inlet makes it easy to supercharge honey and wax mixture into the honey rocket and further increase the honey and wax separation capacity while keeping the feeding process of the honey rocket system clean. As a result the separation result of the honey rocket system is even more dry than in the honey and wax press systems. The result of this process offers a higher honey quality and super low HMF.

CENTRIFUGE SYSTEM

The Centrifuge System is definitely the most powerful tool on the market for the honey and wax separation process. The Centrifuge is designed to meet the needs of professional honey producers for the continuous large scale honey and wax separation.

The honey and wax from the extracting line or other systems is mixed in the stirrer tank. The honey and wax mix is pumped by an inverter controled cappings pump through the vertical heat exchanger and into the centrifuge. The heat exchanger guarantees the optimal temperature for the honey and wax mix. The temperature is adjusted by a digital control system. After the centrifuge, the honey is pumped with a sensor controlled pump from the honey sump into the clarifying tank.

The centrifuge is designed for professional and continuous operation. Now you can concentrate on other tasks while the centrifuge produces clear honey and dry wax. Only our models have the built in lifter for a fast and efficient cleaning of the centrifuge rotor.

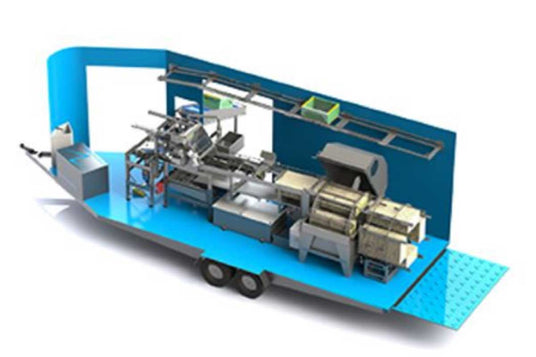

MOBILE EXTRACTING

Main benefits of Mobile Honey Extracting

1. Extraction possibility on site.

2. Work time saving: Only 2 workers are needed to complete the whole work.

3. Fuel economy.

4. Higher profitability per trailer/ operating line.

5. Higher production with time saving management.

6. A better cost effective investment per produced honey / hive.

7. Non disturbing atmospheric conditions.

8. Possibility to return the wet frames back to hives immediately after the extraction.

9. Facility to clean and sanitize anywhere the hives with the pressure washing system.

10. Night extraction possibility (trailers are equipped with LED lights)

11. The trailer is built according to FDA standards.

12. The extraction process can be made in the most optimal place.

13. The stand-alone solution-the generator.

14. The shortest possible extraction cycle.

15. Real-estate investments are useless in order to have hygienic and warm honey extracting environments

OTHER EQUIPMENT

Range of additional equipment by Paradise Honey including honey processing lines, honey filtration systems, heat exchangers and much more.